The importance of gearbox and geared motors across different industries cannot be undermined. Today, with a wide array of designs and brands available in the market buying one which best fulfils all your requirements can be a confusing affair. Whatever be your reasons for purchasing a gearbox or a geared motor it is necessary to keep all factors in mind before you make a purchase.

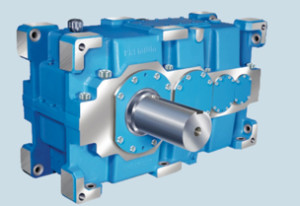

A gearbox is an important mechanical device that helps in varying the motor speed or raising the torque output. Geared motors and gear boxes have become an indispensable part of several applications which require increased horse power and efficacy. Some of the industries where this component is used in a big way are the sugar mills, mining, packaging, oil, presses, rolling mills, power plants, construction projects and many more. Today, there are a lot of geared motor dealers offering a large variety of geared motors and gearboxes to fulfil the demands of big industrial plants as well as small scale industries. Varied materials like brass, aluminium and iron are used for the making of these gears. Some of the varied types of gears available in the market are spur gears, bevel, planetary, worm and helical gears with each one of them differing from the other in terms of efficiency, torque and overall speed. The orientation of the gear teeth and the materials used are two factors that determine the attributes of each gear type. And each type has a specific role to play in the application for which it is used.

Applications which require lesser speeds use gearboxes fitted with straight geared teeth called the spur gears. These go into applications of daily use like washing machines, electric screwdriver, clothes dryer etc. This type is however, quite noisy and low on efficiency. For higher speed requirements it is advisable to use helical gearboxes which are more superior to the spur gears. Several helical gear dealers and inline helical gear dealers, stock top quality helical gears that are noiseless, high on efficiency and less polluting. Bevel gears are useful in applications which require variations in the shaft’s rotation while worm gears are utilized when the speed reduction ratio between non-intersecting crossed axis shafts needs to be large.

There are several factors that have to be borne in mind while buying your gear requirements in order to get the best fit because the size, gear ratio, torque output, load distribution factor and efficiency affect the performance and cost of your gearboxes. The requirements of your application must be in line with the features of the gears under consideration. Selecting the most suitable gearbox and geared motor is one of the biggest tasks for engineers across various industrial segments. The gearbox is the basis of any engine or machine in the industry and it is very much necessary for it to be always in control. Sometimes, while meeting the high torque requirements there are chances of it slipping out of place. So, if you want to optimize the performance of your machines then it is very essential for you to buy your gearbox requirements from a reliable dealer.