Pumps help in moving water or other liquids from one point to the other for a number of applications. The flow of liquids may be needed at normal pressure or high pressure depending upon the application. Centrifugal pumps are named such because they work on the basics of centrifugal force and are normally used for applications which require consistent and cost-effective functioning.

Mechanism

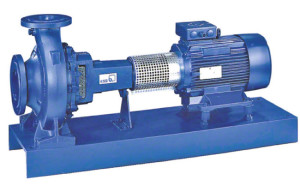

Back pull-out pumps refer to one of the designs of centrifugal pumps. The basic working principle of these pumps is pretty simple. The rotation of the electric engine produces kinetic energy and this generates pressure in the liquid that is to be pumped. The parts that make up the main body of the centrifugal pump are impeller, bearing, axis, seal ring, stuffing box and pump body. The impellers are the ones responsible for getting the movement of the fluid. However, one of the valuable components among all is the mechanical seal which monitors the pressure mounting inside the pump and prevents the leakage of fluid from the insides of the pump.

Applications

The centrifugal pumps are widely used in several applications. Textile industries, environmental plants, food industries, power stations and water desalination plants are just to name a few of them. If one has to be comprehensive then irrigation systems, sugar industry, wine distillery, paper industry, air conditioning, fire-fighting systems and water supply systems of municipal corporations can be quoted as the varied applications of centrifugal pumps. However, the pumps are put to best use in aquatic ponds or sprinkler systems in large gardens. Dam sites are another place where they are needed.

Advantages

The back pull-out design of centrifugal pumps is one of most maintenance friendly designs. The internal parts of the pump can be easily pulled out without disturbing the machinery. This ensures proper inspection and effective repairs to be undertaken. The pumps are robust and provide long service. Suspension can be handled excellently by these pumps and hence they do not need high maintenance. Good efficiency, minimum downtime, low operating costs, ease of maintenance can be summarized as the advantages of the back pull-out centrifugal pump.

Choosing a Good Pump

There are several factors that have to be kept in mind while choosing a centrifugal pump for your application. The pressure requirements and the volume of the application in addition to the material that will be handled form the main considerations. Besides water, fertilizer, oil and other chemicals are also pumped and therefore the horsepower needs more so in terms of volume and discharge pressure have to be looked into.

Reliable Back Pull-Out Pump Dealers

The back pull-out pump dealers will offer proper advice on the factors that have to be given importance after determining the use you will be putting the centrifugal pump for. A single distributor normally stocks various mechanical items like centrifugal pumps, gear boxes, inline helical gears etc. However, while undertaking the purchase of any of these items it is most essential to check out the reliability of the inline helical gear dealers, helical gear dealers and. This will ensure that you get full value worth of your money.