Your gearbox gives you the benefit of use for many years but after a while some problems are bound to occur. Gearbox repairs can be pretty expensive and hence it is better to check out any unusual sounds or vibrations indicating a gearbox problem. Continue reading

Tips to maintain Efficient Working of your Gear Box

In this era of rising costs and prices, it is essential to ensure that your gearbox is operating at optimum efficiency levels. The first concern in case of gearbox failure is the costs to get it running again. At the same time, it is equally important to understand the reasons for the failure and ways in which they can be avoided.A preventive maintenance program becomes a crucial factor in this context as it helps in lengthening the life cycle of your gearbox by minimizing the incidence of failures. Continue reading

Flameproof Electric Motors- Vital for Hazardous Work Environments

An electric motor is an inherent part of any industry. It is a device that converts electrical energy into mechanical energy to be used for industrial applications as diverse as machine tools, industrial fans, pumps and blowers, power tools, household appliances etc. Continue reading

Importance of Lubrication to enhance the Life of your Gear Box

Gearbox forms an important component in many industrial applications as they are used to change the standard speed factor of electric motors. Hence, ensuring their optimum working efficiency is a vital necessity and for this its lubrication system becomes a crucial factor. Continue reading

Keys to Preventing Motor Failure

Electric Motors are the silent workhorses of any industry. They are the ones responsible for the smooth and effective running of the industrial plants. If one of them fails, then it can lead to costly downtime for the plant and disrupt the normal flow of operations. Hence, it is essential to ensure that most of the causes that can lead to motor failures are taken care of. Continue reading

Energy Efficient Motors- Are they worth the Cost?

Energy efficiency in commercial and industrial facilities helps to reduce costs, increase profits and stay ahead of competition. In most of the industrial establishments the major user of energy is the electric motor. Hence, energy efficiency should be a major factor to be considered when buying Crompton Greaves electric motors. Continue reading

Energy efficiency in commercial and industrial facilities helps to reduce costs, increase profits and stay ahead of competition. In most of the industrial establishments the major user of energy is the electric motor. Hence, energy efficiency should be a major factor to be considered when buying Crompton Greaves electric motors. Continue reading

Accelerate Your Savings with AC Drives

CG Drives and Automations have been providing world class motor control equipments to users, operators, system integrators and OEM’s around the world for 35 years. Continue reading

Benefits of Drives and Automation

Speed drives are devices used in machines run on motors. The function of the speed drives is to provide precision motor control so that the motor can be run on optimal speed and use only as much power as is needed, instead of having to run at a fixed speed and consume excess energy. Continue reading

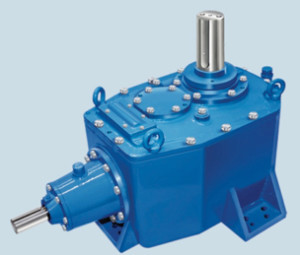

Worm Gearboxes

In order to change the speed (RPM) or the output torque of a motor, a mechanical device needs to be used – a gearbox. The shaft of the motor is attached to one side of the gearbox and offers a given torque as output and speed which is determined by the gear ratio, through the internal arrangement of gears within a gearbox.

Types of Industrial Motors

There are several types of electric motors which include alternating current (AC) motors, direct current (DC) motors, and universal motors. All kinds of industries are required to install some type of motor as part of the driving force behind their production line. Modern technical development has made available a wide variety of electric motors for industrial use.