The wide array of geared motor and gear box available in today’s times makes it quite overwhelming when it comes to making a right choice of the items for your application. The geared motor and the gear box have to be of top quality and at the same time available for a competitive price and hence, finding a balance between the two can be quite difficult.

Tag Archives: Inline helical gear dealers

Components & Purchase Considerations

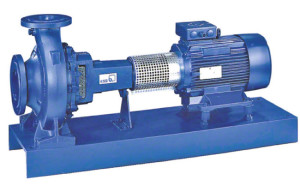

Pumps of several kinds and meant for fulfilling several purposes are available in today’s times. Amongst the whole lot, centrifugal pumps are one variety that is most commonly used in commercial and industrial applications. Centrifugal pump is a mechanical device that helps in transferring several kinds of liquids like water, oil, brine, chemicals or volatile liquids. Staying true to its name, the pumps use centrifugal force to fulfil its function and include all rot dynamic pumps into its fold.

Why is Geared Motors Used in Most Industrial Settings?

Geared motors form the core of all electric motor systems that are produced on a mass scale. From can openers operated on electricity to big washing machines electric geared motors feature in every aspect of our daily life.

Types of Fire Fighting Pumps

When you think of a fire you immediately visualize ringing of fire alarms or fire fighting engines with their long hoses spurting water to douse the flames. Little do we realise that the fire fighting pump is the inconspicuous device that jets out water at required pressures through the fire hydrant so that they can reach high up to the flames and extinguish them. These pumps stand like good soldiers gearing to go into action when a fire emergency presents itself.

Centrifugal Pumps- Components & Purchase Considerations

Pumps of several kinds and meant for fulfilling several purposes are available in today’s times. Amongst the whole lot, centrifugal pumps are one variety that is most commonly used in commercial and industrial applications. Centrifugal pump is a mechanical device that helps in transferring several kinds of liquids like water, oil, brine, chemicals or volatile liquids. Staying true to its name, the pumps use centrifugal force to fulfil its function and include all rot dynamic pumps into its fold.

Brief on Types of Gears Used in Manufacturing Plants

Gearboxes have touched every aspect of our lives today. Gears and gearboxes are being used in a wide range of applications like your own automobile to big and huge machinery in the industrial world. These are available in different sizes, shapes and varying features with all the gear box dealers but whatever be the difference all of them perform the same job and that is altering the input of a transporter into a high speed and torque output.

Back Pull-Out Pumps – One of the Best Designs of Centrifugal Pumps

Pumps help in moving water or other liquids from one point to the other for a number of applications. The flow of liquids may be needed at normal pressure or high pressure depending upon the application. Centrifugal pumps are named such because they work on the basics of centrifugal force and are normally used for applications which require consistent and cost-effective functioning.

A Guide to Purchasing Gear Boxes and Geared Motors for Your Applications

Choosing the most appropriate gearbox and geared motor are some of the biggest concerns of industries and engineers across different industries and verticals. With a host of brands and designs available in the market, selecting a gear box and geared motor that offers excellent output and performance is extremely confusing. Whether you are planning to replace an existing and obsolete gear box or even if you are looking to purchase an entirely new one, take a look at some of the suggestions listed here.

How Does Lubrication Improve The Durability of Greaves Gearboxes?

A gearbox is an essential component that facilitates in industrial operations, as they work by enhancing the speed of different motors used in the system. However, for its optimal performance it is vital to lubricate the gearbox time-to-time. This is because without lubrication friction would be generated at the integral parts of the gearbox leading affecting its efficiency and even leading to innumerable issues.

What Are The Different Types of Industrial Gearbox And How to Maximize Its Performance?

Gearbox is one of the integral components of several industries. They operate as the source of power transmission for almost every form of function that takes place in the industrial sector. With time its industrial application has seen a steep rise, as a result of which manufacturers are producing exceptional range of gearboxes so as to meet the increasing demands.