Electric motors and drives are the silent workhorses when it comes to any process or operation in the mining sector. They are the driving force for any equipment ranging from the highly powerful hoists and crushers to the smaller ones like reagent dosing pumps and more.

In view of this, reliability of the motors assumes great importance as a failed drive or motor on a vital component can in the extreme case bring a halt to the entire operation. And even if idleness is factored in, the loss in processing capacity cannot be avoided till the problem’s rectification. If the equipment in question is a big one then the severity of the impact cannot be imagined; it will be huge. For example, the existence of loose windings in the electric motor driving a mill’s operations can bring the mill’s operations to a standstill for days in a row. The outcome of the review that follows may also cause the motor to be replaced. Therefore, sourcing electric motors from reputable manufacturers is needed if you want the effective functioning of your mill’s operations.

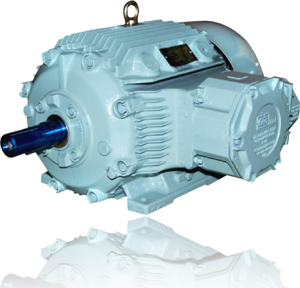

In this context, a mention has to be made of Crompton Greaves electric motors; their electric motors are reliable and dependable for years and years together. Their products include synchronous, hoist-duty and induction motors and they offer solutions for protection of power distribution. Motors may seem to be an inconsequential part of the mining equipment, however, applications necessitate a distinctive and accurate examination of the location, conditions and operational behavior to lay down features of a long lasting electric motor. Sturdy and robust motors that require very less maintenance and ensure continuous operation even in severe conditions are needed for mining operations. Crompton Greaves electric motors dealers and distributors form the source for obtaining such long running electric motors.

If the induction motor required in the mining operation has to be selected correctly then it is essential to know the torque vs. speed curve prerequisites of the driven equipment. To give an example, a centrifugal pump may function effectively with a specific kind of electric motor but the same will be unable to get a full gyratory crusher to speed due to the variance in starting torque requisites.

Quarry duty motors which can offer high starting torque or explosion proof motor or flame retardant motors are some of the products that are of need in mining environments. Better dependability and energy efficiency can be achieved from products that are obtained from dealers or manufacturers who are well established in the business. AC synchronous motors, AC induction motors, DC generators and motors or comprehensive high-output motor generator systems are just a few of the products offered by Crompton Greaves. Their products have found their way into a number of applications and in each of them they have gone on to create a long list of satisfied customers. So, the next time you need to source your electric motors keep the name of reputed manufacturers in mind and then go ahead with your purchase action.