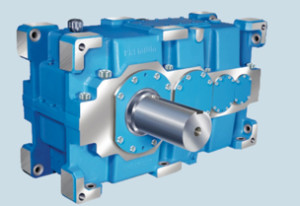

A gearbox is an essential component that facilitates in industrial operations, as they work by enhancing the speed of different motors used in the system. However, for its optimal performance it is vital to lubricate the gearbox time-to-time. This is because without lubrication friction would be generated at the integral parts of the gearbox leading affecting its efficiency and even leading to innumerable issues.

What is the Importance of Lubricating Gearbox?

Lubrication is a fundamental aspect of Greaves gearboxes; in fact it is regarded to the essence of these tools. Now, if the level of lubrication decreases then that would cause gearbox failure, ultimately this failure can causes several expenses in the form of replacement and repairs. The same consequences are even experienced in case of inline helical gears where, the wheel of the gear becomes prone to friction resulting in surface fatigue.

Therefore, there are three important reasons to lubricate the gearbox and they are

Cools the internal components

Gearboxes are made up of gears which is basically a rotating machine meshed with another part so as to transmit torque. These devices have the ability to change torque, speed and even direction of the power. So, when the tooth of the gear rotates then it comes in contact with another toothed part and this is what produces friction. Excess friction can heat the various internal components of the gearbox. Therefore, with the use lubrication friction can be controlled as a result of which the components remain cool.

Protects Metal from Corrosion

Without a doubt the metals that are used in the making of gearboxes are prone to corrosion. Therefore, to prevent this inline helical gear dealers stress upon the importance of lubrication and the difference that it can create to the overall performance of the device. After all, corroded metals will never be able to provide the efficiency that you are looking for, especially for industrial applications.

Prevents wear-tear of the machine

Gears move in a rotational motion, this means continuous rotation without any source of lubricative oil would lead to the wear-tear of the machine. Prolonged wear and tear means endless repair and replacement. Hence, to avoid such hassles it is often advised to lubricate the various parts of the gearbox frequently.

Discovering High Quality Gearbox is Essential Too!

Though lubrication is the key for perfect functioning of gearboxes but before that it is essential to identify reliable geared motor dealers who would come with the quality of devices that you are looking for. As, the combination of both high quality gearboxes along with lubrication would support your industry at its best.

First begin your search for ideal helical gear dealers and then select appropriate lubricative oil that would support in the functioning of the machine and ensure that it works effectively for a long period of time.

Every industry demands for great power from gearboxes, where lubrication can acknowledge this need by providing a superior finish for carrying heavy loads without any sort of complications.