Pumps of several kinds and meant for fulfilling several purposes are available in today’s times. Amongst the whole lot, centrifugal pumps are one variety that is most commonly used in commercial and industrial applications. Centrifugal pump is a mechanical device that helps in transferring several kinds of liquids like water, oil, brine, chemicals or volatile liquids. Staying true to its name, the pumps use centrifugal force to fulfil its function and include all rot dynamic pumps into its fold.

Pumps are of two types; positive displacement pumps and kinetic pumps with the centrifugal pumps coming in the latter category. Depending upon the requirements of the application, centrifugal pumps are available in different sizes, shapes and types ranging from big to small, high pressure to low pressure, meant for transferring liquids to gases etc. The basic structure of a centrifugal pump consists of six parts and they include the following:

- Impeller

- Pump body

- Bearing

- Pump axis

- Seal ring

- Stuffing box

The impeller is the most important component of the pump and its quick rotating speed is responsible for delivering large power. The pump body which is otherwise also called the shell supports the entire equipment. The pump axis transfers the electric motor’s torque to the impeller while the bearing supports the pump axis. The seal ring has an important role to play in the working of the centrifugal pump; it helps to control the inner leakage, prolong the time of operation and increase the reflux resistance. The seal ring is located at the junction of the impeller’s outer edge and the shell’s inner edge. The stuffing box consists of stuffing material, seal cage, water sealing pipe and so on and sealing the gap between the axis and the shell forms its main purpose.

Selecting a good pump is of utmost importance and there are several factors that have to be considered in this regard. The pressure and volume needs of the application and the matter to be pumped are of prime consideration. The material that has to be pumped could be anything ranging from water to fertilizer to oil to any other chemical. The horsepower requirements with regard to discharge pressure and volume are another point of consideration. Centrifugal pumps in these respects are an excellent choice as they are low on maintenance and can deal with suspension efficiently.

One of the best designs of a centrifugal pump is the back pull-out pump as vouched for by the back pull-out pump dealers dueto an added advantage possessed by it. In the back pull-out pump, the back end with the seals, drivers, couplings, shaft end can be removed or dismantled for inspection, maintenance, servicing and overhaul without disturbing the pipework. This is the most preferred choice in refineries where the element of quick dismantling and re-assembly is of importance.

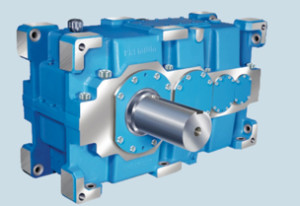

The back pull-out pump dealers are the best people to approach for obtaining the right fit of centrifugal pump for your application. However, the reliability of dealers of all mechanical items such as the back pull-out pump dealers, inline helical gear dealers and helical gear dealers has to be checked out to get top quality products for your application.