Gears are an indispensable component of several machines and motors. They assist in jacking up the torque output by enabling gear reduction and adjusting the direction of shaft rotation to the back wheels of automobiles. Two or more gears operating together one behind the other is called a gearbox. There are varied types of gears like the spur gears, helical gears, bevel gears, and worm gears etc. and each one of them has an important role to play in the varied industrial applications.

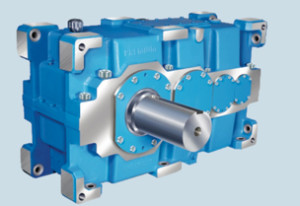

Among them helical gearbox and helical gears are empowered to function smoothly without generating noise as in case of spur gears. This fact will be vouched for by all the helical gear dealers and inline helical gear dealers.Spur gears are in fact, the basic version of gears and helical gears are a refined version of them.Helical gearscan run noiselesslybecause of theirangled teeth that look like part of a helix. The gears are cylindrical gears which do not have their teeth parallel to the rotational axis; instead they are angled. So, at the start of the process, the two teeth begin to engage at a gradual pace, starting at one of the tooth’s end and retaining contact while the gear spins into full engagement. The helix angle’s range is normally around 15 to 30 degree. The typical range of gear ratio is 3:2 to 10:1. Helical gears produce great amounts of thrust; however, they sustain the thrust load with the help of bearings or a special lubricant.

As far as inline helical gears are concerned they can be used in applications which require non-stop working under tough operating conditions. Inline helical geared motor is defined by high torque and slow speed applications. Helical gears can be grouped into two categories namely, Cross helical gears and Double helical gears. Geared motor dealers ensure that adequate stocks of each are available at their end to avoid falling short of customer demand.

Advantages of Helical Gears

- Smooth operation is guaranteed due to the gradual engagement of the angled teeth of helical gears as compared to those of spur gears.

- Helical gearboxes and helical gears are long lasting and most suited for applications involving high loads.

- It is able to conduct power and motion between right angle or parallel shafts.

- Wear and tear is reduced due to load distribution between numerous teeth.

Applications of Helical Gears

Most of the reputed geared motor dealers advise using helical gears in applications requiring heavy load efficiencies and noiseless functioning in automotive applications.The gears are a common feature in transmissions. Some of the industries where the helical gears are commonly used are:

- Printing, earth-moving and fertilizer industries

- Port and power industries, steel and rolling mills

- Textile industries, food industries, plastic industries, elevators, conveyors, compressors, blowers, cutters and oil industries

Besides the above applications, the gears are used in a number of additional applications. Each type of gears has its own set of features and attributes making them suitable for different machines and varied operating conditions.