- +91-9833355333

- sales@scindustrial.com

Articals

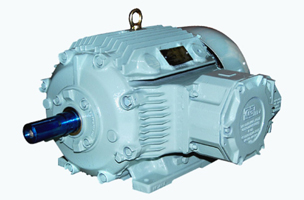

Flameproof Electric Motors- Vital for Hazardous Work Environments

An electric motor is an inherent part of any industry. It is a device that converts electrical energy into mechanical energy to be used for industrial applications as diverse as machine tools, industrial fans, pumps and blowers, power tools, household appliances etc.

Increasingly efficient electric motors were produced throughout the 19th century but their commercial exploitation on a large scale began only in recent times. Today, you have as small an electric motor fitting into a wristwatch as well as large ones which are responsible for propelling huge ships or pipeline compressors. There are various ways of classifying Crompton Greaves electric motors such as by their internal construction, source of electric power, by application or type of motion given.

The flameproof variety of electric motors play a significant role in ensuring safety of operations in industries involving explosive gas dusts and chemicals of various types. Hence the Crompton Greaves flameproof motors finds its way in hazardous areas like the petrochemicals, refineries, underground oil mines, coal mines installed in Zone I and II.

Where are the flameproof motors used?

These motors are used in those areas where large amounts of explosive mixtures are involved in the operations and the occurrence of hazards in the normal course of working are high. In coal mines, petro-chemicals, refineries the use of hazardous material is high. Inflammable gases, fumes, vapours and coal dust which are present pose a natural atmospheric hazard threat. Squirrel cage motors with flameproof enclosures are just what are needed at such places.

What are they made of?

Tough cast iron parts are used to make the flameproof enclosures and these are mechanically very strong and liberally designed. Cast iron is usedso that the enclosure can bear any internal explosion. The entire structure is designed in such a way that no chance is left for the igniting flame to go into the surrounding atmosphere. The design of the motor also ensures that the temperature of the frame will be lesser than the ignition temperature of the concerned gas-air mixture.

The cast iron parts which form a part of the flameproof enclosure are subjected to thorough testing. Hydraulic pressure test is adopted after the final machining is over. Adequate care is taken while machining the seats of joints so that the gaps do not exceed the permissible limits.

For mining applications the motors are provided with cable entries with FLP cable glands.

Certificates of Approval

The test reports issued by Central Mining Research Station, Dhanbad form the basis of approval of the flameproof motors by the concerned authorities.

Certifying authorities include:

![]() The Director General of Mines Safety, Dhanbad

The Director General of Mines Safety, Dhanbad

![]() The Chief Inspector of Explosives, Nagpur.

The Chief Inspector of Explosives, Nagpur.

![]() The Director General of Factory Advice Service and Labour Institute, Mumbai.

The Director General of Factory Advice Service and Labour Institute, Mumbai.

Channel Partners